# Plasma Technology: Transforming Agricultural Equipment for a Sustainable and Efficient Tomorrow

Agriculture has historically served as a fundamental support for society, ensuring human life through a consistent food supply. With the increasing global population and soaring food demands, a critical need has emerged: the demand for more effective and dependable farming tools. Today’s farmers are under growing pressure to yield more while using less time, fewer resources, and maintaining a strong focus on sustainability. Technological advancements have stepped in to aid farmers in these vital processes, with one particular innovation swiftly gaining prominence: **plasma technology**.

This cutting-edge method of swiftly and accurately cutting metal is revolutionizing the production of farming machinery—offering quicker, more economical, and precise solutions for both manufacturers and agricultural practitioners. In this piece, we delve into the ramifications of plasma technology on agricultural tools and its role in redefining the future of agriculture.

## What is Plasma Technology?

At its core, **plasma** is a state of matter in which gas is electrically heated to exceptionally high temperatures, enabling it to conduct electricity. Plasma cutting technology utilizes this principle to incisively cut through metal. Unlike traditional cutting techniques—such as sawing or grinding—that frequently result in rough edges and take more time, plasma cutting delivers clean, smooth, and precise cuts.

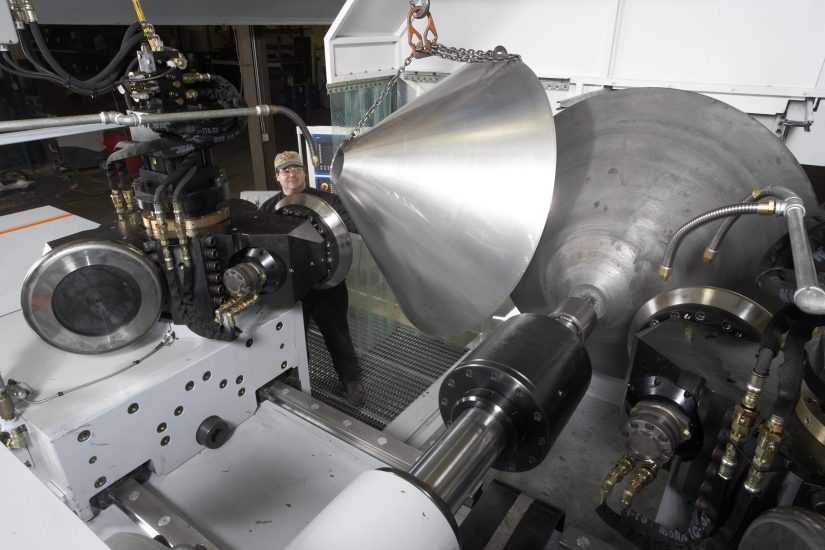

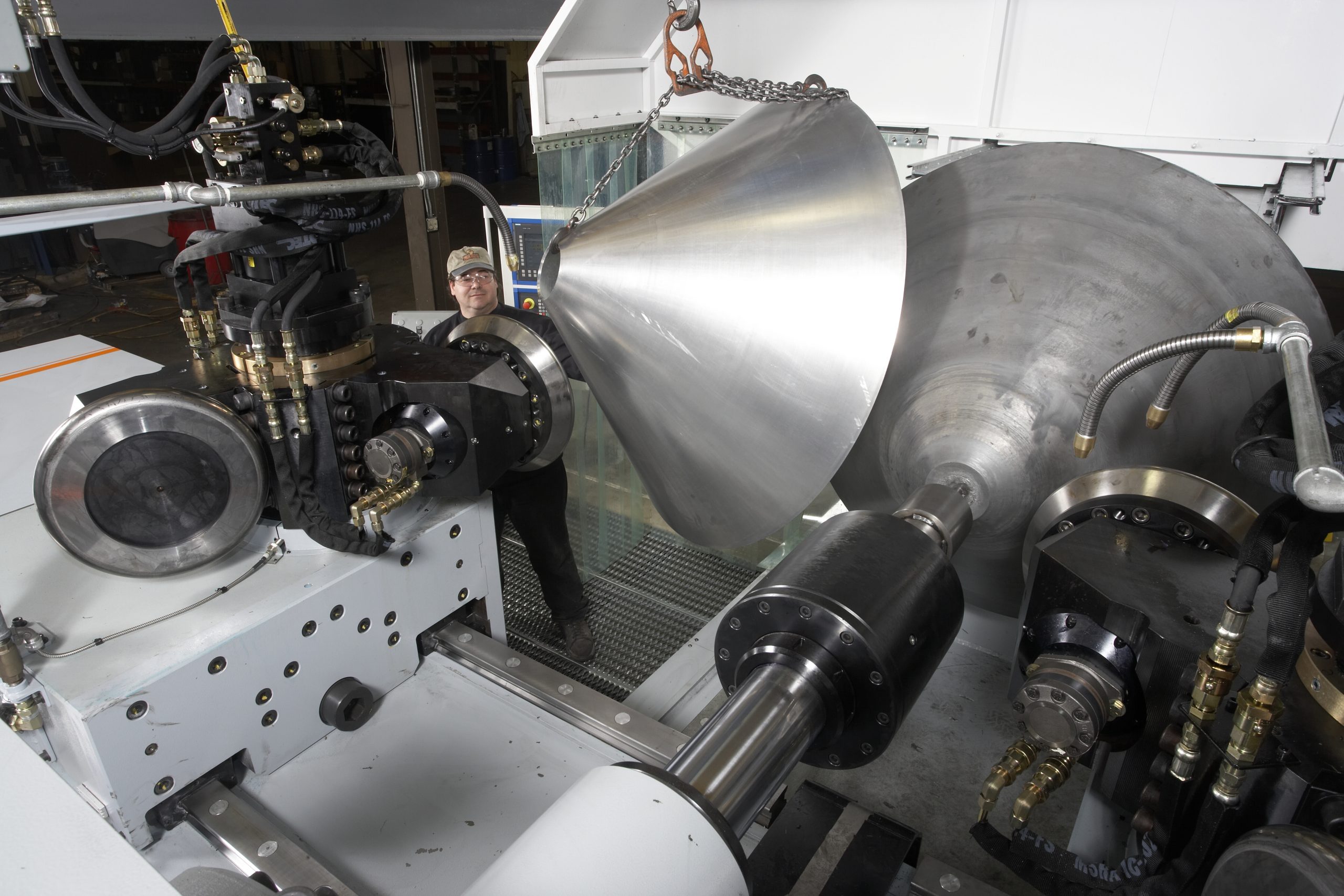

Various industries, including aerospace and automotive, have reaped the benefits of plasma’s accurate and efficient cutting capabilities. Now, the agricultural sector is starting to harness these advantages. Specialized instruments, like **CNC (Computer Numerical Control) plasma tables**, are becoming increasingly prevalent. These devices automate the plasma-cutting process, permitting quick, programmable, and optimized metal cutting that lessens waste and enhances productivity.

For farmers, accessing high-quality, custom-crafted agricultural machinery through services powered by plasma cutting is more accessible than ever. Modern technologies expedite the provision of essential tools with remarkable reliability, reducing the risk of costly downtime and repairs during crucial farming periods.

## The Importance of Plasma Cutting Technology in Agriculture

In agriculture, the performance of machinery is of utmost significance—especially during planting, growing, or harvesting times, when any stoppage could lead to substantial financial losses. Plasma technology distinguishes itself through its speed and precision, effectively addressing equipment malfunction issues with agility and accuracy.

Here are several reasons why plasma cutting is vital for contemporary agriculture:

1. **Quicker Repairs**: Should an essential piece of equipment—like a combine harvester—require a particular part, manufacturers using plasma technology can create custom replacement components in hours instead of days, curtailing delays in farming operations.

2. **Adaptability**: Plasma cutting can cater to a variety of customization needs, simplifying the development of specialized attachments or parts tailored to the distinct requirements of different farms.

3. **Productivity**: Minimizing downtime and enhancing repair processes ensures that farmers operate at optimal productivity during key times in the agricultural calendar.

By providing adaptable, customizable, and expedited solutions, plasma technology is tackling the inefficiencies that have historically hindered farmers.

## Speed and Precision: The Perfect Duo

In agriculture, **speed is crucial**. Every moment spent delaying crop care, seed planting, or harvesting impacts overall productivity. Plasma cutting operates significantly faster than traditional metal cutting methods, yielding results in a shorter timeframe without compromising quality. For manufacturers supplying farming tools, this speed advantage allows them to fulfill consumer needs under pressing timelines.

Alongside speed, **accuracy** is another vital element. Agricultural machinery often operates in challenging environments—whether on uneven ground or in adverse weather conditions—and is subjected to constant strain. The components involved must be robust and dependable to ensure durability. Plasma cutting’s precision mitigates the risk of poorly crafted or unsuitable parts, lessening the likelihood of equipment breakdown. This degree of accuracy instills confidence in farmers that their tools will perform reliably, even in the most challenging settings.

## Economical Solutions for Farmers

Efficiency is not the sole benefit of plasma technology; it also brings considerable **cost savings**. Traditional manufacturing techniques for agricultural equipment can incur high costs due to material wastage and extensive man-hours needed to produce each part. Conversely, plasma cutting systems are meticulously optimized to minimize material waste through precise accuracy and efficient design.

Moreover, by incorporating **automation** into plasma cutting via CNC systems, manufacturers cut down on labor expenses. Once a design is inputted, the machine adheres to exact specifications with minimal human oversight, accelerating the process while diminishing the chance of mistakes.

For farmers, these savings result in **affordable and long-lasting machinery** designed for durability. Whether dealing with a minor component or a major system, the process remains cost-effective for all parties involved, from manufacturers to agricultural practitioners.

## Design Customization Versatility

One of the most remarkable advantages of plasma technology is its **flexibility** in design. Conventional cutting techniques often fall short in their capacity to tackle intricate or complex designs. In contrast, plasma cutters can generate remarkably detailed and tailored patterns, providing great freedom in the design process.

Farmers around the globe confront various challenges.