# The Expanding Significance of Pipe and Tube Bending in the Building Sector

The construction sector is always transforming, with innovative techniques and technologies emerging to address the needs of contemporary society. A significant area that has witnessed substantial progress is the employment of **pipes and tubes**—vital elements in ventures spanning from residential buildings to vast industrial facilities. Whether utilized for plumbing, HVAC setups, or the conveyance of gases and various substances, the proficient use of piping greatly influences the overall functionality, safety, and visual appeal of a structure.

In this context, **pipe and tube bending** has become an essential procedure, facilitating customized shapes that accommodate a variety of project demands. Thanks to technological advancements, the construction field is now better equipped with more effective, precise, and innovative methods to shape pipes and tubes, thereby improving project design and implementation. This article aims to offer a comprehensive examination of the fundamentals of pipe and tube bending, delve into the latest breakthroughs in this field, and investigate how these advancements are shaping the future of construction.

## Understanding Pipe and Tube Bending

Fundamentally, **pipe and tube bending** involves altering pipes or tubes to create a specific contour or angle. Although the terms “pipe” and “tube” are often used synonymously, they generally fulfill slightly different roles. **Pipe bending** tends to involve larger diameter materials, typically employed for fluid transportation, while **tube bending** usually pertains to smaller diameter tubes used in structural applications or systems like HVAC.

### Materials Frequently Used

A variety of materials are commonly employed in pipe and tube bending:

– **Steel** (both carbon and stainless) is preferred for its strength and durability, making it suitable for demanding projects.

– **Copper**, celebrated for its exceptional conductivity and resistance to corrosion, is extensively used in plumbing and heating applications.

– **Aluminum** is valued for being lightweight and resistant to corrosion, making it ideal for outdoor settings, particularly in exposed environments.

### Overview of Equipment

To effectively bend pipes and tubes, specialized tools are necessary. The equipment commonly includes:

– **Hydraulic Benders**, which utilize hydraulic power for precise curves.

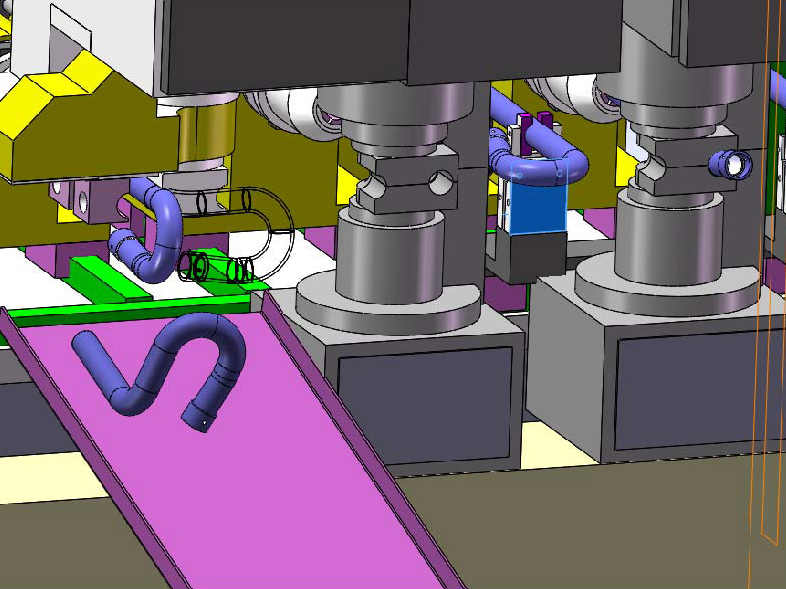

– **Mandrel Benders**, which employ a flexible shaft inserted into the pipe to prevent it from crumpling during the bending process.

These apparatuses are available in both new and pre-owned machinery markets, with a growing number of firms providing quality-assured used equipment at reduced costs. Choosing high-caliber used equipment is an efficient approach for businesses to control expenses while still investing in sophisticated tools.

## Benefits of Pipe and Tube Bending

The capability to bend pipes and tubes offers numerous advantages across various facets of construction:

### 1. Project-Specific Customization

Perhaps the most significant advantage is customization. Pipe and tube bending allows for the formation of curves and shapes that align with the specific design criteria of a project. **HVAC systems**, for example, depend on custom-bent pipes to navigate constrained areas and optimize airflow efficiency. Similarly, intricate **plumbing** systems can gain from tailored designs that improve water flow and visual appeal without compromising the building’s aesthetics.

### 2. Efficient Use of Space

In contemporary construction, particularly in crowded urban locales, space efficiency is crucial. Bent pipes necessitate less material and integrate more smoothly into tight spaces. In **urban settings**, where every inch is precious, the ability to minimize spatial requirements for infrastructure significantly enhances a building’s design and practicality. This enables smarter and more inventive utilization of space for various piping and tubing systems.

### 3. Enhanced Visual Appeal

In addition to functionality, creativity in construction encompasses visual allure. Many modern architects are integrating curved piping into their designs to elevate the **aesthetic value** of structures. Whether the pipes are included in a building’s exterior or contribute to fluid interior designs, well-executed bends can transform essential utilities into visually appealing architectural elements.

## Advancements in Pipe and Tube Bending Technology

With the technological progress of today, the pipe and tube bending process has experienced profound changes. These innovations render the process quicker, more precise, and capable of catering to the increasingly intricate demands of construction.

### 1. Automation and CNC Bending

A key advancement is the incorporation of **CNC (Computer Numerical Control) technology** into bending operations. CNC technology automates the bending procedure by programming machines to execute accurate bends. This lessens the need for manual input, significantly improving both precision and productivity.

Automated CNC bending also reduces errors, resulting in decreased material waste and cutting expenses. Consequently, construction firms can finish projects more swiftly and within financial constraints.

### 2. Innovative Software Solutions

Software advancements are similarly impacting the future of pipe and tube bending. Contemporary design software enables engineers and designers to **simulate bends and configurations** in a virtual setting prior to any physical alteration of materials. This “design-before-execution” methodology promotes informed decision-making based on reliable simulations, helping to avert costly errors or reconstructive work.

### 3. Emergence of New Materials and Methods